1060 hot expansion production line

It is the advanced equipment for hot expansion processing of seamless steel pipes developed by the Company. It has the remarkable characteristics of high processing efficiency and high precision grade. It can process seamless steel pipes up to OD1,060 mm and offer 700 tons of pushing force to meet the customers’ demands for production and processing of hot expansion pipes with large diameter and super wall thickness.

Large-diameter six-roller straightener

It is an advanced large straightening device in China and mainly used for straightening of large-diameter thick-wall seamless steel pipes. It has been developed and tested by the Company itself based on the actual needs for application, and undergone a number of optimization and improvement. It has achieved enhanced productivity and durability after improvement, and has double advantages of high straightening efficiency and high precision.

Universal hydraulic testing machine

It is mainly used for tensile, compression, bending, shear tests, etc, on metal and non-metal materials. It can be extensively used in / by building materials, metallurgy, scientific research institutes, colleges and universities, quality inspection centers and commodity inspection agencies, and is the ideal testing machine for production, scientific research, teaching, etc. Its design is based on standard GB/T16826-2008 “Electro-hydraulic Servo Universal Testing Machine”.

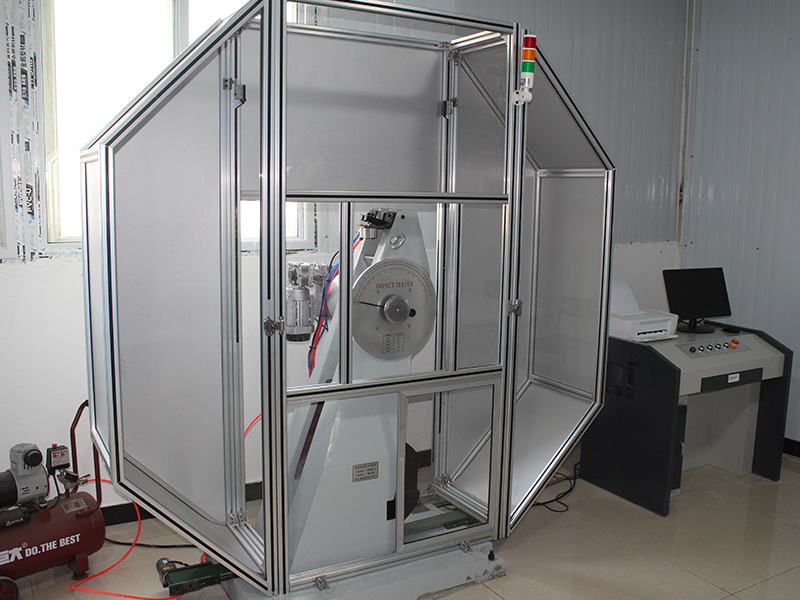

JBW-750C micro-control impact testing machine

This testing machine is equipped with a double-cutter hydraulic broaching machine for impact specimens, a DWC-60 impact test cryogenometer and a CST-50 impact notch projector. It is used to determine the performance of metallic materials to resist impact under dynamic load in order to determine the natures of the materials under dynamic load. This testing machine has been developed according to GB/T229-2020 “Metallic Materials - Charpy Pendulum Impact Test Method” and manufactured According to GB/T3808-2020 “Pendulum Impact Testing Machine Inspection”, and used for impact tests on metallic materials. It gives maximum impact energy 750J. The cross section of the standard sample used is 10x10x55 mm. It is mainly used for impact test on ferrous metals with high impact toughness, especially steel and its alloys.

Φ258POF tube rolling line

This line is mainly composed of the equipment such as a circular heating furnace, a conical piercing machine, a 6-stand limited-core POF continuous rolling machine, a 3-silver 14-stand sizing machine, a 6-roller vertical oblique rolling and straightening machine, etc. The reverse replacement stand of the 258 POF continuous rolling machine and 4-stand core rod support device can significantly reduce the consumption of the online threading tool and offer uniform temperature, making the product highly competitive.

Φ720 rotary pipe expansion unit

This unit is mainly composed of a stepper heating furnace, a 720 rotary pipe expander, a push forming and leveling machine (piercing machine), a five-stand sizing machine, an undercar normalizing & annealing furnace, a hydraulic pressure straightening machine, etc. It is mainly used to produce large-diameter thick-wall pipes.

Φ460POF tube rolling line

This line is mainly composed of a circular heating furnace, a conical-roller piercing machine, a 5-stand limited core rod POF continuous rolling machines, a 3-Jiang-type 14-stand sizing machine, a 6-silver vertical oblique roller straightening machine, etc. It is a three-roller continuous rolling production line for large-diameter pipes, and also a large continuous rolling unit for large-diameter pipes in the world. Compared with other units of the same caliber, this unit has obvious advantages in producing large-diameter high alloy products which are hard to be rolled. Its features of high finished product yield, low labor consumption and low rolling costs have established its ideal position.

Heat treatment line

It is used for processing of the stainless pot tube, high alloy tube, boiler tube, etc. The advanced equipment ensures that the pot tube can always achieve the ideal quality.

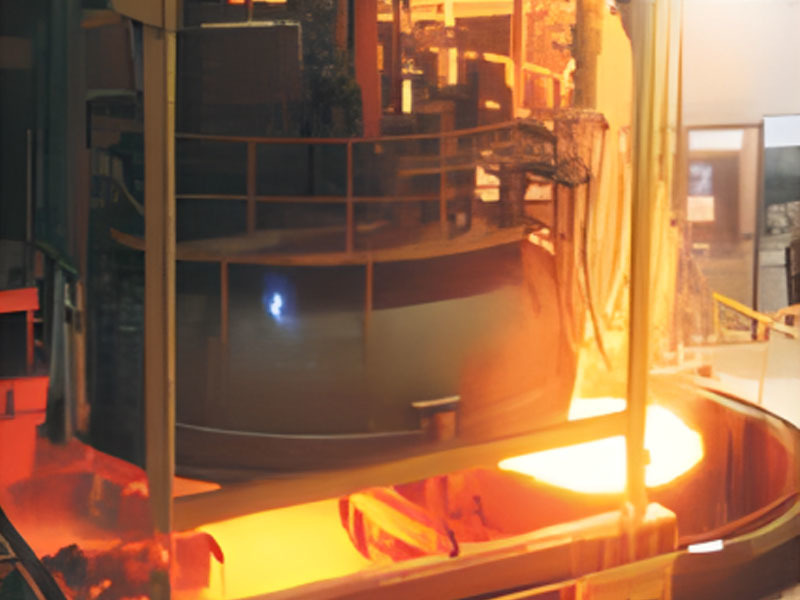

150t electric furnace system

It is composed of a 150t ultra-high power electric furnace, an LF outer refining furnace, a VD vacuum degassing furnace, a pot-bottom ammonia blowing unit, a wire feeder, a six-flow circular continuous casting equipment, etc. All the equipment was introduced from Mannesmann Demark GmbH in Germany. It can produce five kinds of continuous casting pipe blanks with diameters of medium 400 mm, medium 350 mm, 310 mm, medium 270 mm and medium 210 mm.

90t electric furnace system

It is composed of a 90t ultra-high power electric arc furnace, an LF outer refining furnace, a VD vacuum degassing furnace, a pot-bottom ammonia blowing unit, a wire feeder, a six-flow continuous casting machine for rectangular and round billets, etc. The main equipment was introduced from Italy, and the other equipment was made in China. It can produce five kinds of rectangular / round pipe blanks with diameters of 270 mm, medium 251 mm, 210 mm, 150 mm and 150 mmX150 mm.

All rights reserved©2022 Tianjin Tengfei Steel Pipe Co., Ltd. www.300.cn |SEO Tags